All published articles of this journal are available on ScienceDirect.

Early-Stage Enhancement of Engineering Properties of Low Plastic Silt Using Waste Glass Powder

Abstract

Introduction

Soil stabilization is crucial for preventing foundation instability and enhancing the longevity of structures underlain by weak subsoil layers. Incorporating environmentally friendly soil amendments, such as Waste Glass Powder (WGP), is a practical approach among various stabilization techniques for shallow applications. This study explored the early-stage applicability of WGP for enhancing the mechanical properties of soil classified as ML under the Unified Soil Classification System (USCS).

Methods

Crushed WGP, obtained from recycled glass, was blended with soil at 2%, 4%, 6%, 8%, 10%, and 12% by dry weight. The effects were assessed through Liquid and Plastic Limits (LL & PL), standard proctor compaction, Unconfined Compressive Strength (UCS), and California Bearing Ratio (CBR) tests.

Results

The test results indicated that WGP reduced the plasticity of soil, lowering the Liquid Limit (LL), Plastic Limit (PL), and Plasticity Index (PI) to 18, 14, and 4, respectively, at 12% WGP. The Maximum Dry Density (MDD) increased up to 8% WGP before declining, while the Optimum Moisture Content (OMC) showed a consistent decrease. The 7-day UCS peaked at 210 kN/m2 with a 6% WGP, representing a 53.3% improvement over untreated soil, before decreasing to 136 kN/m2 at a 12% WGP content. Additionally, the 7-day CBR values showed significant enhancement when WGP was added. Both unsoaked and soaked CBR increased, and the highest values were discovered to be 31 and 13, respectively.

Discussion

This research highlights that utilizing WGP supports environmental sustainability by diverting waste from landfills and reducing environmental hazards. Furthermore, it minimizes dependence on conventional binders like cement and lime, thereby lowering carbon emissions. According to the results presented here, a 6% to 8% WGP may be optimal for enhancing soil properties at the early stage of improvement, especially for low plastic silt, providing an economical and environmentally compatible approach to soil stabilization.

Conclusion

The findings of this study strongly support earlier investigations underscoring the prospect of WGP as a sustainable substitute for conventional stabilizers in geotechnical engineering applications. The viability of using WGP to stabilize other soil types, particularly problematic soils, should be rigorously explored to establish its long-term sustainability.

1. INTRODUCTION

The geotechnical properties of soils play a critical role in the stability and performance of various civil engineering structures, including roads, embankments, and foundations [1, 2]. However, due to their inherent characteristics, soils often pose construction challenges, including excessive settlement, swelling, shrinkage, and reduced load-bearing capacity, thereby complicating infrastructure development [3-6]. As a result, improving the engineering properties of soil has been a focal point of extensive research in geotechnical engineering [7-11]. Traditional soil stabilization techniques commonly utilize the use of chemical additives such as cement and lime to enhance the strength and durability of soils [12-16]. Although effective, these methods pose environmental concerns, particularly due to the high energy consumption and CO2 emissions associated with the production of cement and lime. Concerns over the long-term sustainability of these materials also arise from the significant natural resources required for extraction and processing [17-19]. Thus, identifying alternative, environmentally friendly soil stabilization materials without compromising engineering performance is essential [20-26].

Among the promising eco-friendly methods, utilizing waste materials for soil stabilization stands out due to its substantial environmental and engineering benefits. The construction and manufacturing industries generate massive quantities of waste, much of which remains underutilized [27-32]. Recycling and repurposing waste materials not only mitigate environmental pollution but also provide economic advantages by reducing disposal costs [33]. Among various waste materials, Waste Glass Powder (WGP) has gained attention as a potential soil stabilizer due to its pozzolanic properties and widespread availability [34-38]. Besides application in soil improvement, waste glass in the form of both powder and coarse aggregate has been successfully utilized in assessing the engineering properties of various construction materials, including asphalt mixtures [39-42]. Without strongly emphasizing recycling initiatives, waste glass disposal will become an increasingly critical environmental challenge. Converting waste glass into a valuable engineering material presents a viable and sustainable solution, particularly in the field of geotechnical engineering [43-48].

The pozzolanic properties of WGP render it an appropriate stabilizing agent for soils. Cementitious substances are formed when WGP is combined with soil and undergoes a pozzolanic reaction with calcium hydroxide and water [34, 35, 38, 49-52]. In the absence of cement or lime, cementitious compounds may also form in soils that naturally contain calcium-bearing minerals or free calcium hydroxide in alkaline water [28, 53, 54]. These cementitious substances enhance the bonding between soil particles, resulting in improved compaction characteristics, increased compressive strength, and reduced permeability. Furthermore, WGP may act as a filler, resulting in more mechanical interlocking, thus increasing the internal friction of the soil matrix [37, 48, 55-58]. This makes WGP a viable alternative to conventional stabilizers, particularly in regions where industrial byproducts and construction waste are readily available [59-61]. Despite earlier studies examining the effects of other waste products, such as fly ash and rice husk ash, on soil stabilization, research on the geotechnical applications of WGP remains limited [62-65]. Comprehensive investigations are necessary to assess the WGP’s efficacy in enhancing soils under diverse conditions, including different soil compositions, moisture contents, and curing periods [66-71].

Baldovino, Izzo, Silva, and Rose [72] conducted a comprehensive experimental investigation on the stabilization of high-plasticity silt (MH) using varying proportions of WGP (5%, 15%, and 30% by dry weight) and cement (3%, 6%, and 9%). Their study assessed the influence of these additives on different curing durations. The results indicated a positive correlation between the additive content and Unconfined Compressive Strength (UCS), with additional improvements in durability observed as curing time increased. The enhancement in performance was attributed to the pozzolanic activity of WGP and cementitious materials. Canakci, Al-Kaki, and Celik [54] explored the application of Waste Soda-Lime Glass Powder (WSLGP) in stabilizing low-plasticity Clay (CL). The WSLGP was incorporated in varying percentages (3%, 6%, 9%, and 12% by dry weight). The study reported a significant reduction in Plasticity Index (PI), Optimum Moisture Content (OMC), and swell potential with increasing WSLGP content. Concurrently, the California Bearing Ratio (CBR) and Maximum Dry Density (MDD) exhibited notable improvements, underscoring the potential of WSLGP to enhance soil strength and reduce volumetric instability.

Ibrahim, Mawlood, and Alshkane [73] added WGP ranging from 6% to 36% by weight to high-plasticity clay (CH) to investigate the effects of WGP on soil properties. The test results demonstrated that adding WGP generally increased MDD and decreased OMC. UCS values increased progressively up to 27% WGP, after which a decline was observed, suggesting an optimal dosage threshold. Furthermore, consistency parameters such as Liquid and Plastic Limits (LL and PL), PI, linear shrinkage, and free swelling index were significantly reduced, enhancing the treated soil’s dimensional stability. Olufowobi, Ogundoju, Michael, and Aderinlewo [36] focused on the combined effectiveness of Glass Powder (GP) and cement in clayey soil stabilization. Using 15% cement and varying GP content (1%, 2%, 5%, 10%, and 15%), the study found that MDD peaked at 5% GP before declining, while OMC decreased consistently. 5% GP produced the highest CBR values in both soaked and unsoaked circumstances. Meanwhile, the highest apparent cohesion parameter and internal friction angle values occurred at 10% GP, leading the authors to recommend an optimal GP range of 5–10% when used with cement for efficient soil stabilization.

The combined use of crushed glass and waste High-Density Polyethylene (HDPE) in subgrade stabilization was examined by Fauzi, Djauhari, and Juniansyah Fauzi [53]. Additive contents of 4%, 8%, and 12% were assessed. Incorporating these wastes resulted in a reduced liquid limit and cohesion, while CBR values and the angle of internal friction improved, indicating an enhanced bearing capacity and shear strength. Similarly, Fauzi, Rahman, and Jauhari [28] studied the utilization of HDPE with glass to stabilize clayey soils. Their findings corroborated earlier results, showing considerable improvement in CBR and geotechnical parameters upon increasing additive content. The study reinforced the viability of such materials in improving the performance of clayey subgrades. Karim, Kundiri, and Mohammed [74] evaluated black cotton soil treated with different combinations of WGP (0%, 5%, 10%, 15%, and 20%) and cement (0%, 2%, 4%, 6%, and 8%) contents. Results revealed that both UCS and CBR increased with the incorporation of WGP and cement. The optimal stabilization performance was achieved at a 20% WGP and 8% cement content. Additionally, consistency limits were found to decrease significantly, thereby improving soil workability and strength. Several researchers have investigated the utilization of Waste Glass Powder (WGP) to enhance the characteristics of both expansive and non-expansive soils.

These studies demonstrate that incorporating WGP into various problematic soils can significantly improve their strength, density, and durability, either alone or in conjunction with other additives. The pozzolanic reaction, particle packing effect, and reduction of soil plasticity are primarily responsible for the observed improvements, which establish WGP as a promising material for sustainable soil stabilization [75, 76]. A thorough understanding of these factors will facilitate the establishment of optimized stabilization strategies that maximize the benefits of WGP. Currently available literature indicates that there is an insufficient investigation into the effectiveness of WGP on the mechanical properties of low plastic silt (ML) soil. These types of soil are usually problematic due to their intrinsically unsuitable engineering properties, including low shear strength and bearing capacity, making them unfavorable for direct use in foundations or pavements [77-80]. Additionally, unacceptable differential settlements resulting in significant structural damage may occur due to the high compressibility of these soils [81]. Other problematic behaviors of low-plastic silt soils may be further pointed out, but are not limited to poor compaction characteristics, rapid loss of strength upon wetting and under dynamic loading, susceptibility to liquefaction in seismic events, erosion, slope instability, frost heave, and thaw weakening in cold climates [79-87].As low-plasticity silt soils are often associated with problematic behaviors, improving their properties is crucial to enhance their strength and reduce compressibility, thereby safeguarding long-term performance and stability in geotechnical engineering applications. Therefore, a comprehensive laboratory testing program was conducted to evaluate the impact of WGP on the engineering properties of ML soil. Different amounts of WGP (2%, 4%, 6%, 8%, 10%, and 12% by dry weight) were added to the soil. Atterberg limits (LL and PL), standard Proctor compaction, unconfined compressive strength, and California bearing ratio tests were conducted on both untreated and WGP-treated samples. Particular attention was directed toward early-stage improvement within 7 days of curing. The 7-day strength of stabilized soils in pavement construction provides a crucial measure of short-term performance required to ensure that subgrade and other layers can withstand initial construction and traffic loads. It may be essential to meet the rapid construction schedules [88, 89]. This early-stage strength may reflect the rate of strength gain, efficiency of the stabilizer, and assist in identifying optimal stabilizer content, thus resulting in cost and material optimization without disobeying the required specifications [79, 90-92]. Thus, assessing the early-stage behavior of WGP-treated low-plastic silt soils will offer valuable insights into both the immediate and long-term effectiveness of WGP. All test results presented in this study revealed that the inclusion of WGP improves the mechanical properties of ML soil at the early stage, indicating it as a sustainable soil amendment.

2. MATERIALS AND METHODS

A comprehensive laboratory experiment-based approach was used to conduct the current research. First, the required materials, such as soil and WGP, were acquired. The soil was then subjected to laboratory tests, including Atterberg limits, specific gravity, and grain size distribution, to categorize it under the Unified Soil Classification System. This made comprehending the natural soil’s properties easier, which are essential for subsequent testing. Broken waste glasses were used to acquire the WGP. The WGP must be evenly distributed throughout the soil sample to produce reliable results. To determine the maximum dry density and optimum moisture content of the untreated and treated soils, both the soil alone and the soil-WGP mixture were subjected to the standard Proctor compaction test. An additional laboratory investigation was conducted to learn more about the effects of WGP on natural soil. CBR and unconfined compression strength were tested using a range of WGP percentages.

2.1. Materials

The natural soil was carefully collected from a construction site in Rajshahi, Bangladesh. The soil sample was taken between 2 and 3 meters deep to ensure a comprehensive understanding of its characteristics, as soil properties can vary significantly with depth. The soil sample was carefully stored to prevent contamination, and large lumps of soil were pulverized to ensure uniformity before being kept in an oven-dry state for further laboratory testing. In this study, waste glass was obtained from the Nanomaterials & Ceramic Engineering (NCE) Department laboratory and crushed using a machine crusher in the transportation engineering laboratory of the Civil Engineering (CE) Department at the Bangladesh University of Engineering and Technology (BUET). All laboratory tests were conducted using potable tap water, which was deemed suitable in this case, as this type of water is commonly used in construction sites. However, to ensure the accuracy of the test results, the same water source was used consistently throughout the testing process. (Fig. 1) illustrates the mixing process of WGP with soil.

Mixing WGP with soil.

2.1.1. Properties of Natural Soil and WGP

The specific gravity of natural soil, determined as per ASTM standard [93], was found to be 2.74, a value typical of silty soils. The Atterberg limit test, conducted using the Casagrande apparatus [94], yielded a liquid limit of 36, a plastic limit of 25, and a plasticity index of 11, indicating a low plastic soil with limited expansiveness. The natural soil sample was identified as low-plasticity silt (ML) based on the Unified Soil Classification System [95]. Hydrometer analysis [96] revealed that the sample consisted of 81.5% silt and 18.5% clay, confirming its fine-grained nature. Table 1 presents the acquired properties, establishing the baseline behavior of the untreated soil before modification with WGP. The specific gravity of WGP was 2.58, as confirmed by the NCE department of BUET.

| Properties | Values |

|---|---|

| Soil Classification | ML |

| Silt (%) | 81.5 |

| Clay (%) | 18.5 |

| Specific Gravity | 2.74 |

| Liquid Limit | 36 |

| Plastic Limit | 25 |

| Plasticity Index | 11 |

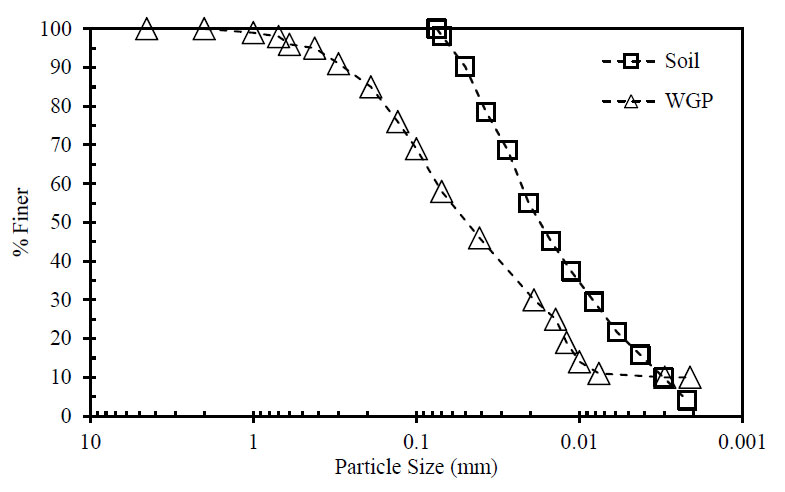

The particle size distribution curve presented in Fig. (2) depicts the distribution of soil particles in the given sample. From the distribution curve, the key particle size diameters for the soil sample were determined as follows: D10 = 0.002 mm, D30 = 0.008 mm, and D60 = 0.02 mm. Based on these values, the coefficient of uniformity (Cu) and coefficient of curvature (Cc) for the soil were calculated to be 10 and 1.6, respectively. Similarly, for the WGP, the corresponding particle size diameters, determined from the grain size distribution [96, 97], were observed as D10 = 0.003 mm, D30 = 0.019 mm, and D60 = 0.08 mm. The calculated values of Cu and Cc for WGP were 26.67 and 1.504, respectively, reflecting a material with a uniform particle distribution that is suitable for enhancing soil structure when used as an additive. Overall, the WGP particles are coarser than the untreated soil.

Grain size distribution of the soil and WGP samples.

2.1.2. Microstructural Analysis

An X-Ray Fluorescence (XRF) spectrometer is a versatile tool for non-destructive chemical analysis of various materials, including geological samples. By utilizing the interaction of X-rays with atoms, XRF spectrometers can determine the elemental composition of rocks, minerals, sediments, fluids, etc. An XRF facility (Model: XEF-1800 SHIMADZU), as shown in Fig. (3a), available in the NCE department of BUET, was used to determine the chemical composition of the untreated soil and WGP samples. The surface of the samples can be observed in high resolution using a Scanning Electron Microscope (SEM), which enables a thorough analysis of their morphology. Additionally, Energy Dispersive X-ray Spectroscopy (EDS) determines the sample's elemental composition by detecting X-rays emitted when the sample is exposed to an electron beam. Together, SEM-EDS allows for simultaneous imaging and elemental analysis. A SEM facility (Model: JEOL JSM-7600F instrument operating at an accelerating voltage of 10 kV and a probe current of 1.0000 nA), available in the NCE department of BUET, was used to determine the elemental composition and map the untreated soil and WGP samples, as shown in Fig. (3b). The images were captured at magnifications of 1000X and 300X. Elemental maps were also obtained to observe the spatial distribution of key elements in the soil and WGP samples.

(a) X-ray Fluorescence (XRF) and (b) Scanning Electron Microscopy (SEM) facility at NCE laboratory, BUET.

2.1.3. Morphological Observation from SEM Images

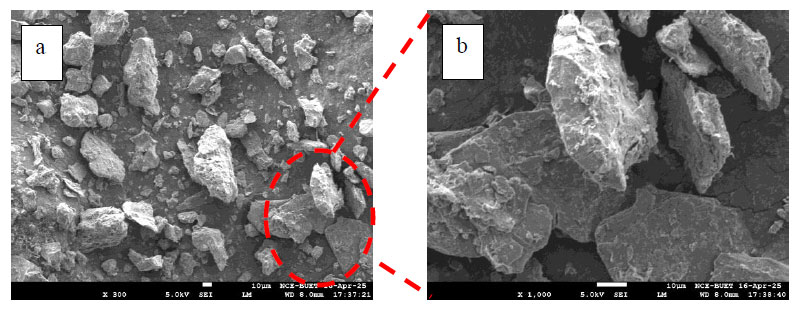

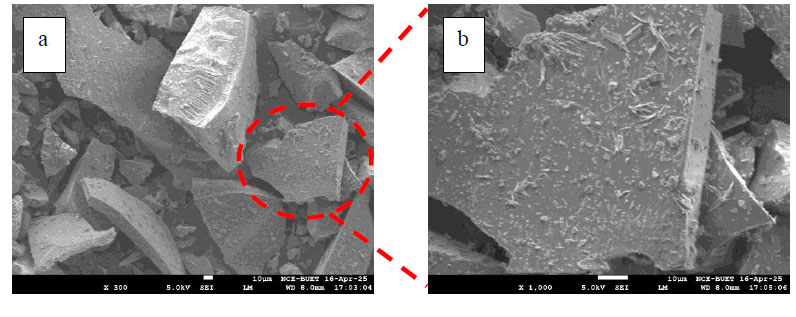

Microstructural observation via SEM imaging revealed significant morphological differences between untreated soil and WGP. The SEM image of untreated soil, as shown in Fig. (4), clearly shows granular morphology indicative of minerals that form mostly cohesionless soil. As the untreated soil is classified as low plastic silt (ML), the morphology of the soil particles, as revealed by SEM images, may be justified. In contrast, WGP particles exhibited angular, sharp-edged structures with smooth and mostly regular surfaces, as demonstrated in Fig. (5). Moreover, comparative assessment of the SEM images indicates that WGP particles are larger than those of the untreated soil sample. This observation aligns with the corresponding particle size distribution curve, confirming the coarser nature of WGP. The combined morphological and size characteristics suggest that the WGP incorporation could positively influence the geotechnical behavior of soil-WGP mixtures.

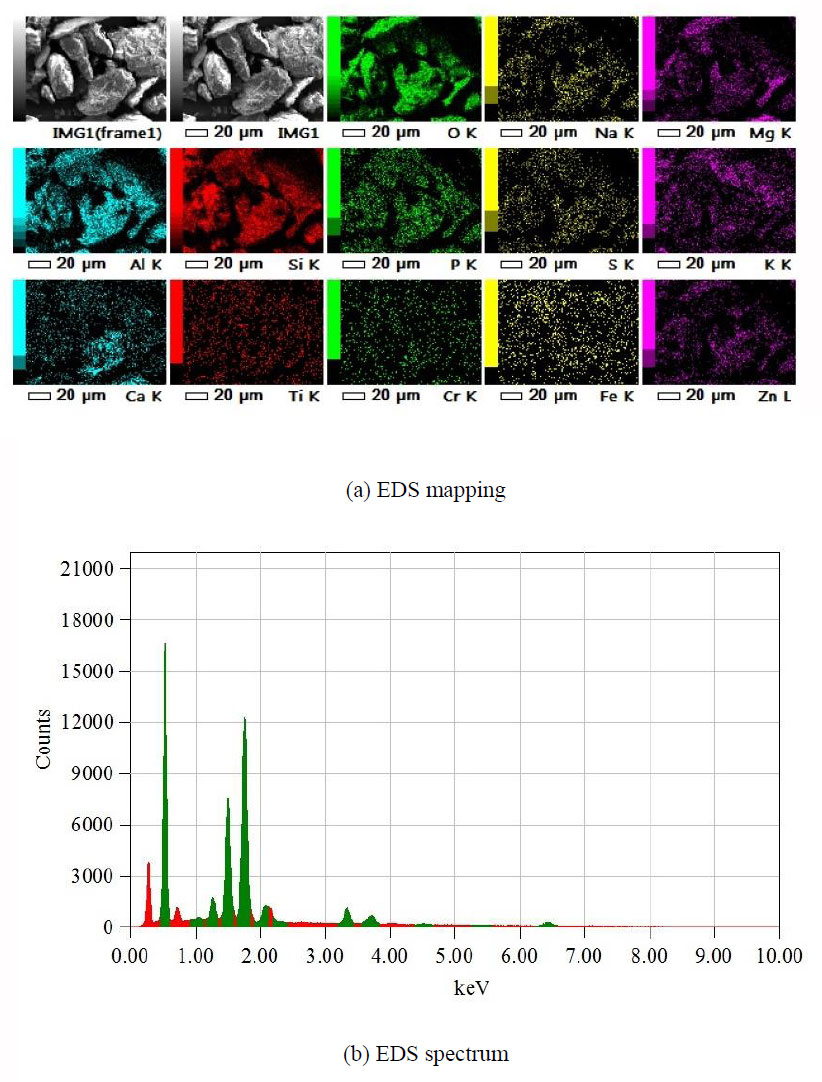

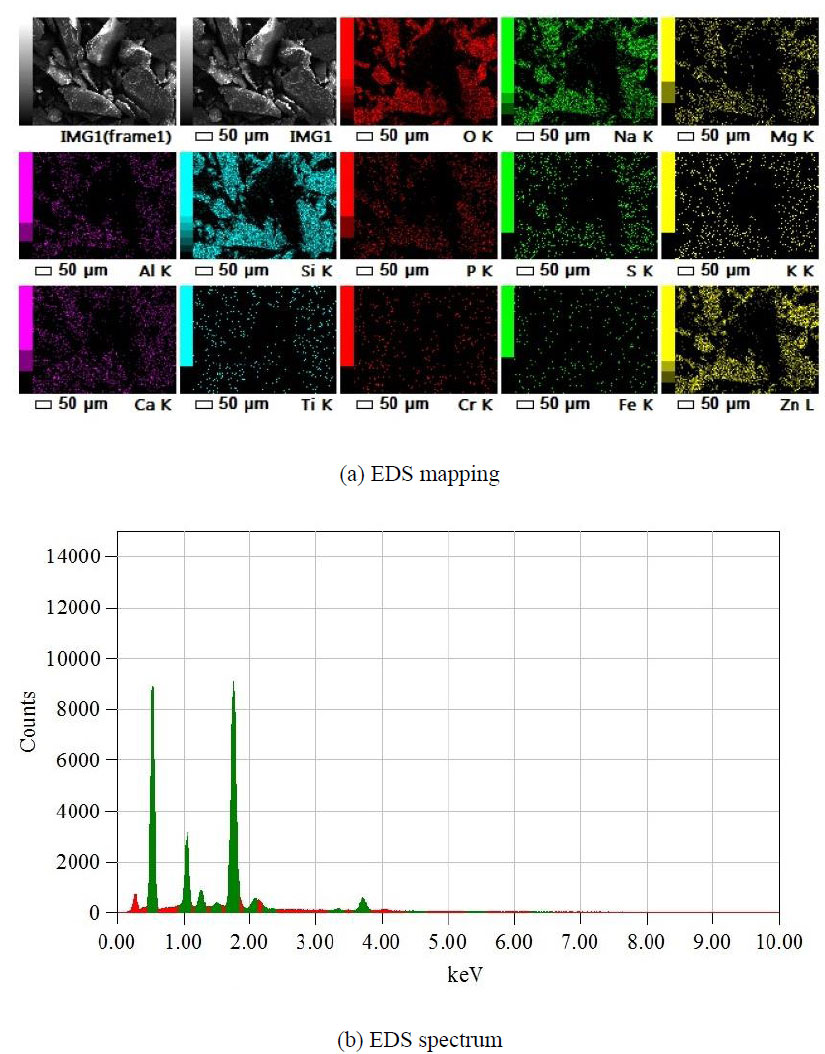

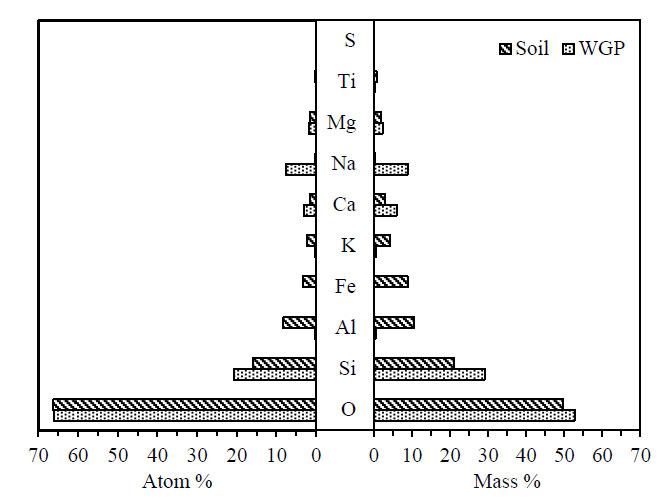

2.1.4. Elemental Composition from EDS Analysis

Figs. (6 and 7) illustrate the SEM-EDS analysis results of the untreated soil and WGP samples, respectively. The summary of the analysis, as presented in Fig. (8), indicates that the soil sample was rich in oxygen (49.6 wt.%) and silicon (21.0 wt.%), with notable amounts of aluminum (10.5 wt.%) and iron (8.8 wt.%), which are typical of silicate and aluminosilicate minerals. The dominance of silicate minerals, along with some aluminosilicates, in the soil indicates the presence of low plastic silt-type materials. The WGP sample showed a higher oxygen (52.7 wt.%) and silicon (29.1 wt.%) content, along with lower iron and aluminum content. Minor elements such as Na, K, Ca, Ti, and Mg were also detected in both samples, although their proportions were generally higher in the WGP sample.

2.1.5. Chemical Properties of WGP from XRF Analysis

XRF analysis results revealed that the WGP sample is primarily composed of SiO2 (76.41%), followed by Na2O (11.94%), CaO (5.24%), and MgO (3.53%) as presented in Table 2. The high silica content and presence of alkali oxides enhance the pozzolanic potential of WGP, enabling it to react with aluminosilicate to form cementitious compounds.

SEM images of the soil sample at (a) 300X, (b) 1000X magnification.

SEM images of WGP at (a) 300X, (b) 1000X magnification.

SEM-EDS analysis results of the untreated soil sample.

SEM-EDS analysis results of the WGP.

Quantitative elemental composition of soil and WGP from EDS analysis.

| Analyte | Content (%) |

|---|---|

| SiO2 | 76.4082 |

| Na2O | 11.9447 |

| CaO | 5.2386 |

| MgO | 3.5284 |

| Fe2O3 | 1.0050 |

| Al2O3 | 0.6844 |

| K2O | 0.2977 |

| TiO2 | 0.2568 |

| SO3 | 0.2355 |

| ZnO | 0.2286 |

| Cr2O3 | 0.1165 |

| P2O5 | 0.0556 |

2.2. Experimental Methods

All laboratory tests, including tests on natural soil and soil-WGP mixture, followed the guidelines provided by the American Society for Testing and Materials (ASTM). Table 3 provides a comprehensive list of laboratory experiments and their corresponding ASTM standard designations. The untreated soil and WGP were sieved through a No. 200 sieve (0.075 mm) and a No. 4 sieve (4.75 mm), respectively [98]. The materials passing through these sieves were used for all laboratory experiments. The particle size distribution of the untreated soil was determined using hydrometer analysis (ASTM 152H hydrometer), whereas the particle size distribution of WGP was determined using both sieve and hydrometer analyses. The liquid and plastic limits, as well as the specific gravity, were determined for the untreated soil only. The standard Proctor compaction test (compaction energy: 600 kN-m/m3), as per the ASTM standard [99], was conducted for the untreated soil and soil-WGP mixtures with varying amounts of WGP by dry weight (i.e., 2%, 4%, 6%, 8%, 10%, and 12%). The UCS [100] and CBR [101] samples were prepared using the OMC, and nearly 95% of MDD, corresponding to each percentage of WGP content. The UCS and unsoaked CBR samples were air-cured for seven days, whereas the soaked ones were cured in water for 7 days instead of the standard 96 hours. These tests were conducted immediately after the 7-day curing period was completed.

3. RESULTS

3.1. Effects of WGP on Soil Index Properties

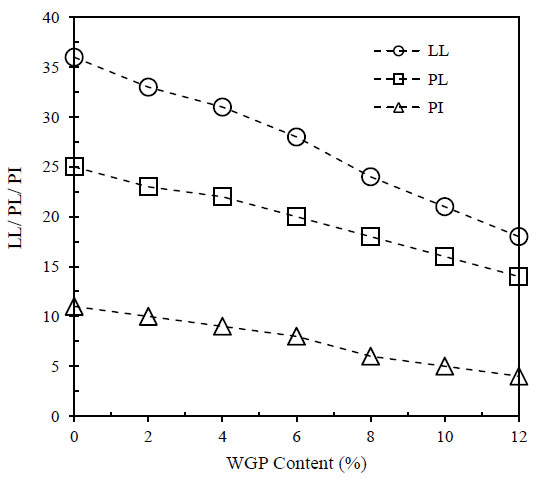

The effects of WGP on the liquid limit, plastic limit, and plasticity index of soil-WGP mixtures for different percentages (i.e., 2%, 4%, 6%, 8%, 10%, and 12%) of WGP by dry weight are illustrated in Fig. (9). As shown in Fig. (9), due to the addition of WGP, the liquid limit reduced from 36 (untreated) to 18 at 12% WGP, while the plastic limit decreased from 25 to 14. As a result, there was a corresponding decrease in plasticity index from 11 to 4. Other researchers also reported similar observations [28, 36, 37, 53, 73, 74]. This behavior can be attributed to the increased workability, reduced water retention capacity, and reduced long-term compressibility potential of the treated soil, which are many of the primary requirements of soil stabilization techniques.

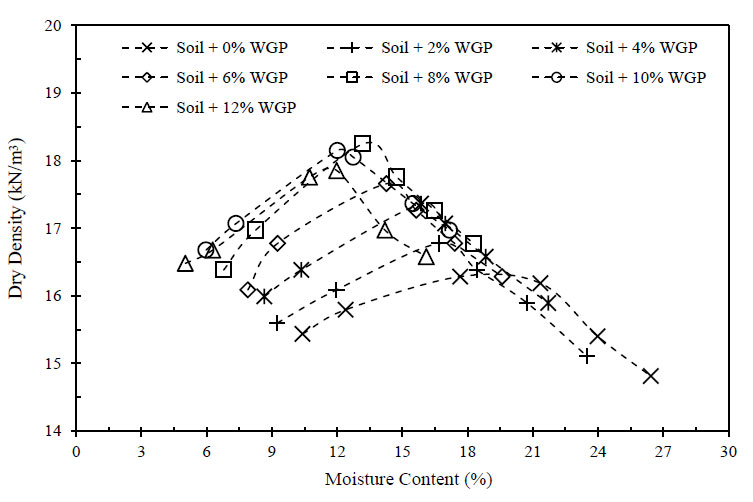

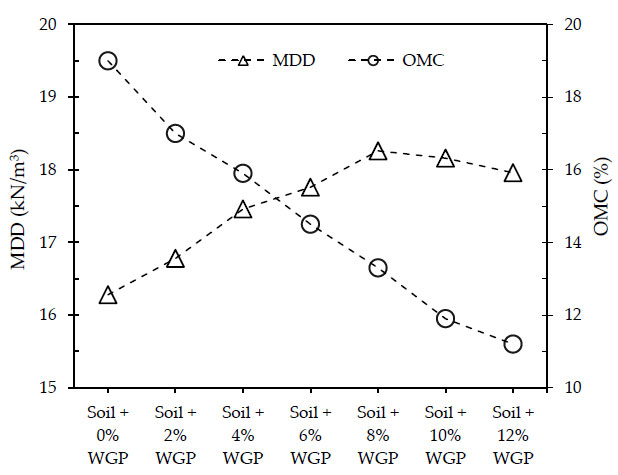

3.2. Effects of WGP on Compaction Characteristics Of Soil-WGP Mixtures

The effects of WGP on MDD and OMC for different percentages (i.e., 2%, 4%, 6%, 8%, 10%, and 12%) of WGP by dry weight are illustrated in Fig. (10), which presents the variation of dry density with moisture content for soil and soil-WGP mixtures. A notable shift in the compaction curves towards the upper left corner is observed with the addition of WGP, which is typically expected for soils that are similarly improved. Several investigators have reported the shift of the compaction curves due to the addition of WGP [28, 36, 37, 53, 73, 74]. The MDD of the untreated soil was 16.28 kN/m3 and increased to 18.26 kN/m3 when 8% of WGP was added, and then started to decrease after further addition of WGP. On the contrary, OMC decreased from 19.0% to 11.8% by adding up to 12% WGP, suggesting improved compaction behavior. The denser packing is due to the angularity and granular nature of WGP, which fills the voids within the soil matrix. (Fig. 11) summarizes this trend by plotting MDD and OMC against WGP content. These results suggest that a WGP content of nearly 8% by dry weight, which falls within the range of values reported by other researchers [28, 36, 37, 53, 73, 74], may be considered as the optimum amount for stabilizing low plastic silt-type soil at the early stage.

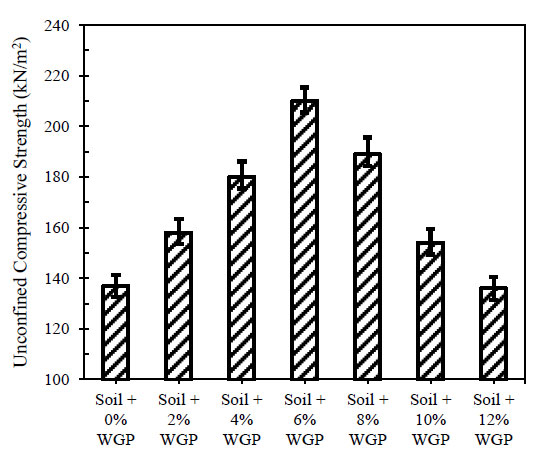

3.3. Effects of WGP on Unconfined Compressive Strength Of Soil-WGP Mixtures

The UCS results of soil-WGP mixtures are illustrated in Fig. (12). The unconfined compressive strength increased significantly with the addition of WGP, peaking at 210 kN/m2 for 6% WGP, compared to 137 kN/m2 for untreated soil. Beyond this percentage (i.e., 6%), the strength declined to 136 kN/m2 at 12% WGP. This trend may suggest an optimum dosage of WGP of 6% for low plastic silt-type soil under early improvement conditions. The optimum WGP content of 6% found here aligns with the range of values reported in earlier studies [28, 36, 37, 53, 73, 74].

| Sl. No | Name of Experiment | ASTM Designation |

|---|---|---|

| 1 | Specific gravity of soil solids | ASTM D854-02 [93] |

| 2 | Atterberg limits | ASTM D4318-05 [94] |

| 3 | Hydrometer analysis | ASTM D7928-17 [96] |

| 4 | Sieve analysis | ASTM D6913-04 [97] |

| 5 | Compaction (standard Proctor) | ASTM D698-00AE01 [99] |

| 6 | Unconfined compression | ASTM D2166M-24 [100] |

| 7 | California bearing ratio | ASTM D1883-21 [101] |

Variation of LL, PL, and PI values for different WGP content.

Compaction test results of untreated Soil and soil-WGP mixtures.

Variation of maximum dry density and optimum moisture content with different percentages of WGP.

Variation of UCS value (mean ± SD) for different WGP content.

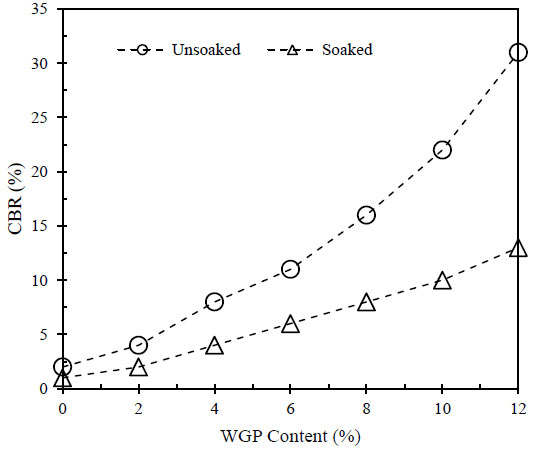

3.4. Effects of WGP on the California Bearing Ratio Of Soil-WGP Mixtures

The CBR test results, both for soaked and unsoaked conditions, reveal a significant improvement in bearing capacity with the incorporation of WGP into the soil, as shown in the corresponding graph in Fig. (13). The unsoaked CBR value improved from 2 to 31, while the soaked CBR increased from 1 to 13 due to the addition of WGP into the soil sample, as was similarly observed in the earlier investigations [28, 36, 37, 53, 73, 74]. The early-stage enhancement in CBR reflects improved shear strength and load distribution behavior, which may be attributed to the positive particle interlocking from the angular glass particles. These results establish the WGP as a viable, stabilizing, environmentally friendly agent in geotechnical applications.

Variation of CBR value for different WGP content.

4. DISCUSSION

The experimental results highlight the effectiveness of WGP as a sustainable soil stabilizer during the early stages of the curing period. The reduction in liquid and plastic limits confirms the loss of plasticity and increase of workability, aligning with findings from earlier studies [28, 36, 37, 53, 73, 74]. The marked decrease in limits with increasing WGP content can be attributed to the glass powder’s non-plastic nature and its role in diluting the cohesive fraction. The decline in plasticity is beneficial for reducing volumetric changes in soils. The enhanced maximum dry density and reduced optimum moisture content at 8% of WGP content reflect improved packing efficiency due to the granular nature of WGP. These trends are consistent with other studies that utilized industrial waste products for soil improvement [28, 36, 37, 53, 73, 74]. The reduction in optimum moisture content also suggests that WGP-amended soils may require less water during compaction, contributing to sustainable construction practices.

The observed maximum peak in the unconfined compression test at 6% WGP content may indicate an optimal dosage for low plastic silt under early age conditions, warranting further investigation for practical applications. Beyond this percentage, excessive soil replacement by WGP particles appears to reduce interparticle bonding, thus decreasing strength. Similar findings were also reported in the studies using WGP as a soil stabilizer [28, 36, 37, 53, 73, 74]. The 7-day California bearing ratio values of the soil-WGP mixtures demonstrated a steady increase with increasing WGP content, suggesting improved resistance to penetration and enhanced load-bearing behavior. This type of improvement, also reported by others [28, 36, 37, 53, 73, 74], is particularly significant in unsoaked conditions, highlighting WGP’s potential in road subgrade, sub-base, and base applications [28, 36, 37, 39, 40, 53, 73, 74].

Chemically, the high amorphous SiO2 content of WGP may promote self-pozzolanic reactions when mixed with soil containing reactive alumina and calcium sources. This will result in the formation of cementitious compounds, which enhance the strength and stiffness of soil-WGP mixtures. In addition, WGP may act as a micro-filler within the soil fabric, enhancing particle interlocking and contact efficiency, which in turn augments the mobilized internal friction angle. The reduced plasticity, increased density, and improved mechanical properties collectively confirm that WGP is a viable, eco-friendly alternative for geotechnical stabilization. The study identified an optimal range of WGP content from 6% to 8% for achieving significant improvements in the mechanical properties of low-plastic silt-type soil at the early stage of improvement. Exceeding this range may lead to diminishing returns or even adverse effects. Using WGP as a soil amendment offers a sustainable solution for waste glass management, reducing landfill waste and conserving natural resources.

CONCLUSION

This study evaluated the influence of Waste Glass Powder (WGP) on the early-stage physical and mechanical behavior of low-plasticity silt. Based on laboratory investigations, the untreated soil was classified as ML with low plasticity and fine-grained composition. X-ray Fluorescence (XRF), Scanning Electron Microscopy (SEM), and Energy Dispersive X-ray Spectroscopy (EDS) analyses revealed the morphological and chemical differences between the untreated soil matrix and WGP, highlighting WGP's suitability as a soil amendment. Adding WGP up to 12% by dry weight significantly reduced the Atterberg limits by 44% to 64% of the initial values of untreated soil, indicating reduced plasticity and improved volumetric stability. The maximum dry density increased by 7%, and the optimum moisture content decreased by 30% due to the addition of 8% WGP, thereby improving compaction behavior. The 7-day unconfined compressive strength increased to 1.5 times the initial value of untreated soil at 6% WGP, beyond which a reduction in strength occurred. The 7-day California Bearing Ratio (CBR) values in both soaked and unsoaked conditions showed a notable increase of around 13 to 16 times the initial values of untreated soil, thereby enhancing the load-bearing characteristics of the soil. The results presented in this study indicate that an optimum WGP content of 6% to 8% by dry weight of untreated soil is required for low plastic silt (ML) during the early stage of curing. The findings of this study align with earlier research, reinforcing the suitability of WGP as a sustainable soil amendment. However, these findings warrant further validation under extended curing periods (e.g., 14, 21, and 28 days), which are identified as directions for future scope of work. Nevertheless, future research should extend to aspects such as long-term strength, durability, permeability, swelling, and leachability, thereby providing a more holistic understanding of the WGP’s potential applications.

AUTHORS’ CONTRIBUTIONS

T.A., M.F.A., AND A.T. contributed to conceptualization and methodology. T.A. and M.F.A. performed formal analysis and data curation. T.A., M.F.A., and A.T. carried out the investigation, provided resources, prepared the original draft, conducted review and editing, and handled visualization. supervision was provided by M.F.A. all authors have read and agreed to the published version of the manuscript.

LIST OF ABBREVIATIONS

| CBR | = California Bearing Ratio |

| EDS | = Energy Dispersive Spectroscopy |

| HDPE | = High-Density Polyethylene |

| LL | = Liquid limit |

| MDD | = Maximum Dry Density |

| OMC | = Optimum Moisture Content |

| PI | = Plasticity Index |

| PL | = Plastic limit |

| SEM | = Scanning Electron Microscopy |

| UCS | = Unconfined Compression Strength |

| USCS | = Unified Soil Classification System |

| WGP | = Waste Glass Powder |

| WSLGP | = Waste Soda-Lime Glass Powder |

| XRF | = X-Ray Fluorescence |

AVAILABILITY OF DATA AND MATERIALS

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author(s).

ACKNOWLEDGEMENTS

The authors would like to acknowledge the administrative and technical support provided by the Laboratory Instructor of the Geotechnical Engineering Laboratory, Bangladesh University of Engineering and Technology, Dhaka-1000, Bangladesh.